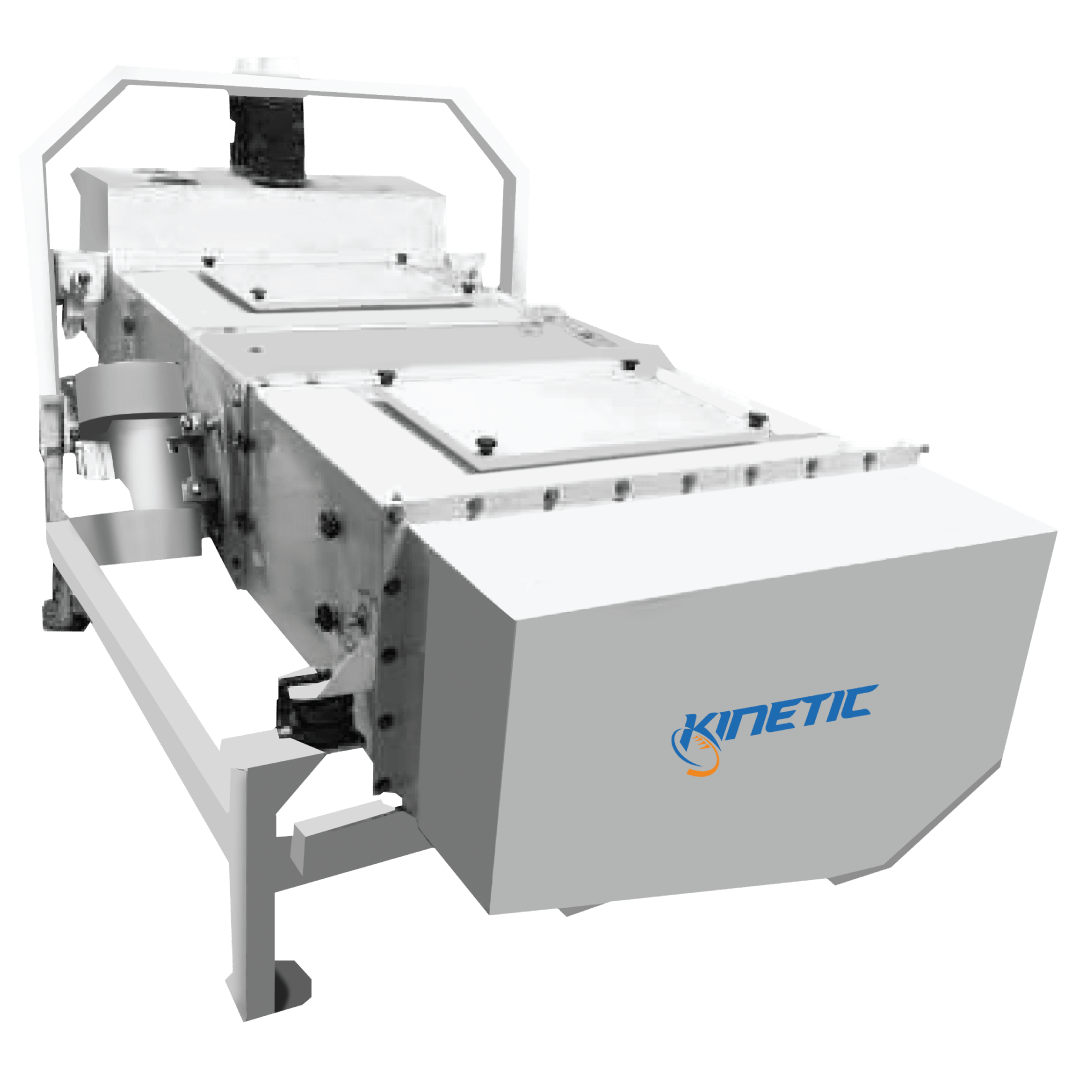

In the field of material separation and processing, dependability and efficiency are critical. The KTS Tip Separator from Kinetic Group is an essential component of any industrial setting since it performs well in each of these areas. Let’s examine what makes this machine an exceptional performer within its class.

Strong Drive System

The sturdy driving system of the KTS Tip Separator, which has two motors with a combined output of 0.75KW, is its core component. This two-motor arrangement guarantees reliable and strong performance, offering the required force to easily handle a variety of materials. The KTS Tip Separator is designed to handle both coarser and finer particles with equal ease.

Creative Design for Sieve Box

The oscillating sieve box of the KTS Tip Separator is one of its most amazing characteristics. With its two decks of sieves, this box facilitates effective material separation. Its adaptability is increased by the two-way movable intake box, which allows it to adjust to various operational requirements. This design lowers the possibility of clogging and downtime by ensuring that materials are treated easily and effectively.

Robust and Unwavering Support Structure

Any industrial equipment must be stable, and the KTS Tip Separator is excellent in this regard. Mounted on the machine frame are hollow rubber springs that support the sieve box. By efficiently reducing vibrations, these springs create a stable working environment. This guarantees steady performance over time and extends the machine’s lifespan.

Superior Quality Clothes and Sieve Frames

The KTS Tip Separator’s sieve frames and sieve clothing are of the highest caliber. These parts are made to endure the demands of constant use, guaranteeing their effectiveness over an extended length of time. The fine-quality sieve cover helps with accurate material separation, increasing the machine’s overall efficiency.

Cleaning of Sieves Automatically

Industrial machinery maintenance is a major worry, but the KTS Tip Separator solves this issue with its automated sieve cleaning technology. By keeping the sieves clear of obstructions and clean, this function reduces the need for physical intervention. In addition to saving time, this guarantees that the system always runs as efficiently as possible.

Adaptable Vibro Motors

Two vibro motors that may be adjusted for impel angle and throw are powering the KTS Tip Separator. With this function, operators may adjust the machine’s performance to meet the needs of different materials and separation processes. With these settings adjustable, the KTS Tip Separator can handle a variety of materials with accuracy and effectiveness.

Applications and Benefits

The KTS Tip Separator is ideal for various industries, including food processing, pharmaceuticals, and chemicals. Its robust design and advanced features make it a reliable choice for any application requiring precise material separation. The machine’s ability to handle different materials with ease makes it a versatile tool in any industrial setup.

In summary

In summary, Kinetic Group’s KTS Tip Separator is a strong, dependable, and efficient device built to handle the demands of contemporary industrial processes. It performs better than other models in its class thanks to its unique features, which include two 0.75KW drive motors, an oscillating sieve box, a strong support system, premium sieve frames, automated cleaning, and adjustable vibro motors. The KTS Tip Separator is a great option for a machine that combines dependability and efficiency. Invest in this equipment to improve the performance and efficiency of your material separation processes.

By integrating the KTS Tip Separator into your operations, you boost productivity and ensure that your processes run smoothly with minimal maintenance. The KTS Tip Separator is a testament to Kinetic Group’s commitment to quality and innovation in industrial machinery.