Maintaining high standards of quality and safety is crucial in the dynamic field of food production. More than ever, modern consumers are knowledgeable and picky, expecting items that not only fulfill but also go beyond safety regulations. Food manufacturers, therefore, continuously look for creative ways to improve their procedures. The KSMI Color Sorting Technology is one such ground-breaking invention that is transforming food safety and quality control.

KSMI Color Sorting Technology: An Overview

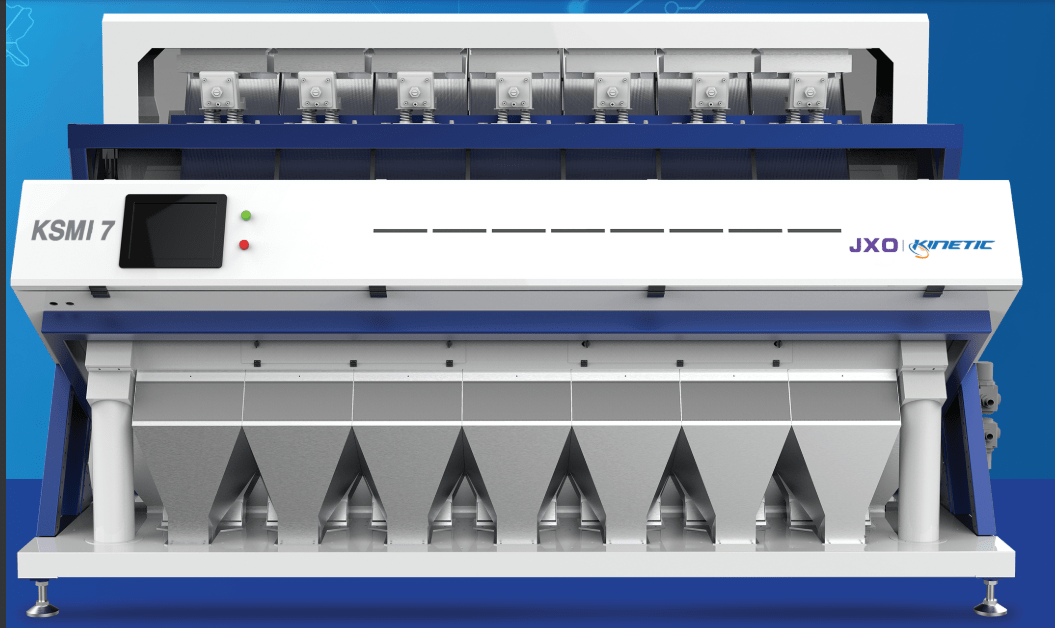

KSMI Color Sorters use advanced optical sorting technology to identify and eliminate foreign elements or faulty items from food supplies. Using high-resolution cameras and complex algorithms, these devices assess and categorize goods according to color, size, form, and other visual characteristics. The precision and speed of KSMI Color Sorters ensure that only the best quality products make it to the market, minimizing the risk of contamination and ensuring consumer safety.

Improving Food Safety

For both consumers and producers, food safety is a top priority. Significant health dangers are associated with contaminants, including glass, stones, insects, and other foreign things. Conventional techniques for identifying and eliminating these pollutants are frequently less efficient and time-consuming. KSMI Color Sorters provide high-accuracy, real-time sorting, making them a superior option.

Modern sensors on these devices are capable of picking up even the tiniest pollutants. After being recognized, the faulty products are removed from the manufacturing line by the sorter using precise ejection mechanisms. This automated procedure guarantees better quality control by lowering the possibility of human mistakes while improving food safety.

Enhancing Quality Assurance

Another area in which KSMI Color Sorters excels is quality control. Apart from eliminating impurities, these devices are engineered to arrange goods according to particular standards of excellence. For example, the sorter may detect under-ripe, over-ripe, or damaged objects in grains or nuts by differentiating between distinct color tones.

Because they can sort things with such accuracy, manufacturers can regularly supply the market with high-quality goods. This degree of quality control is especially crucial in sectors like fruits and vegetables, where consumer choice is heavily influenced by product appearance.

Boosting Efficiency and Reducing Waste

Efficiency Gains and Waste Reduction Efficiency is a key benefit provided by KSMI Color Sorters. Conventional sorting techniques can involve a significant amount of physical work and time, which raises operating costs and reduces production rates. By streamlining the sorting procedure, KSMI Color Sorters greatly boost throughput and minimize the need for manual intervention.

Furthermore, by removing only faulty products and keeping as much of the excellent goods as possible, these robots contribute to waste reduction. Reducing food waste helps with ecological initiatives in addition to economic savings.

Adjusting to Needs in Industry

In order to meet the demands of various industries and a broad variety of food products, KSMI Color Sorters are made to be flexible and adaptive. These devices can be tailored to fulfill individual needs for sorting grains, nuts, seeds, and other food products. Their adaptability renders them a priceless resource for manufacturers seeking to improve their workflow and satisfy the dynamic needs of the market.

Future Prospects for Food Safety and Quality Control

The capabilities of KSMI Color Sorters should increase much more as technology develops. More integration with other automated systems, better algorithms, and improved sensor technologies are possible future advances. These developments will enhance sorting much further, providing even greater precision and effectiveness.

Furthermore, by combining machine learning and artificial intelligence, KSMI Color Sorters may be able to learn new skills and adjust to new situations over time, ultimately enhancing their performance.

In summary

Innovative technology such as KSMI Color Sorters holds great promise for the future of food safety and quality management. These devices are revolutionizing the food sector with their unmatched accuracy, efficiency, and versatility. Future developments in color sorting technology will surely be vital to guarantee that food items are as safe and high-quality as feasible for customers.